-

By admin

-

January 8, 2026

- 3 Comment

Choosing the Right Electrical Conduits for UAE’s Extreme Climate: A Guide to Heat-Resistant Materials

In the high-stakes world of UAE construction and infrastructure, the integrity of an electrical system is only as strong as the conduit that protects it. With summer surface temperatures frequently soaring above 50°C and the relentless Arabian sun providing a constant barrage of UV radiation, standard materials that work in temperate climates often fail here.

For engineers, contractors, and facility managers in Dubai, Abu Dhabi, and the Northern Emirates, selecting the right conduit is a strategic decision that impacts the long-term safety, compliance, and maintenance costs of a building. This guide explores the essential materials and technical considerations required to withstand the UAE’s unique environmental stressors.

“We can easily manage if we will only take, each day, the burden appointed to it. But the load will be too heavy for us if we carry yesterday’s burden over again today, and then add the burden of the morrow before we are required to bear it factorial non.”

Rebert Kosta

The Thermal Challenge: Beyond Just High Temperatures

When a conduit is installed on a rooftop or an exposed exterior wall, it can reach internal temperatures significantly higher than the recorded weather report. If the material is not rated for these extremes, it can lose its structural rigidity, leading to “sagging” between supports. More dangerously, substandard plastics can undergo molecular breakdown, becoming brittle and cracking under the slightest mechanical pressure, leaving live wires exposed to the elements.

The Thermal Challenge: Beyond Just High Temperatures

1. High-Impact, UV-Stabilized uPVC (Class 4)

Unplasticized Polyvinyl Chloride (uPVC) is the backbone of most electrical installations in the region. However, in the UAE, not all uPVC is created equal. For local projects, Heavy Gauge (Class 4) piping is the standard. These conduits are infused with specific chemical stabilizers that prevent the sun’s ultraviolet rays from bleaching and weakening the plastic—a process often called “sun-rotting.” These are ideal for underground burial and internal wall chasing where moisture resistance is key.

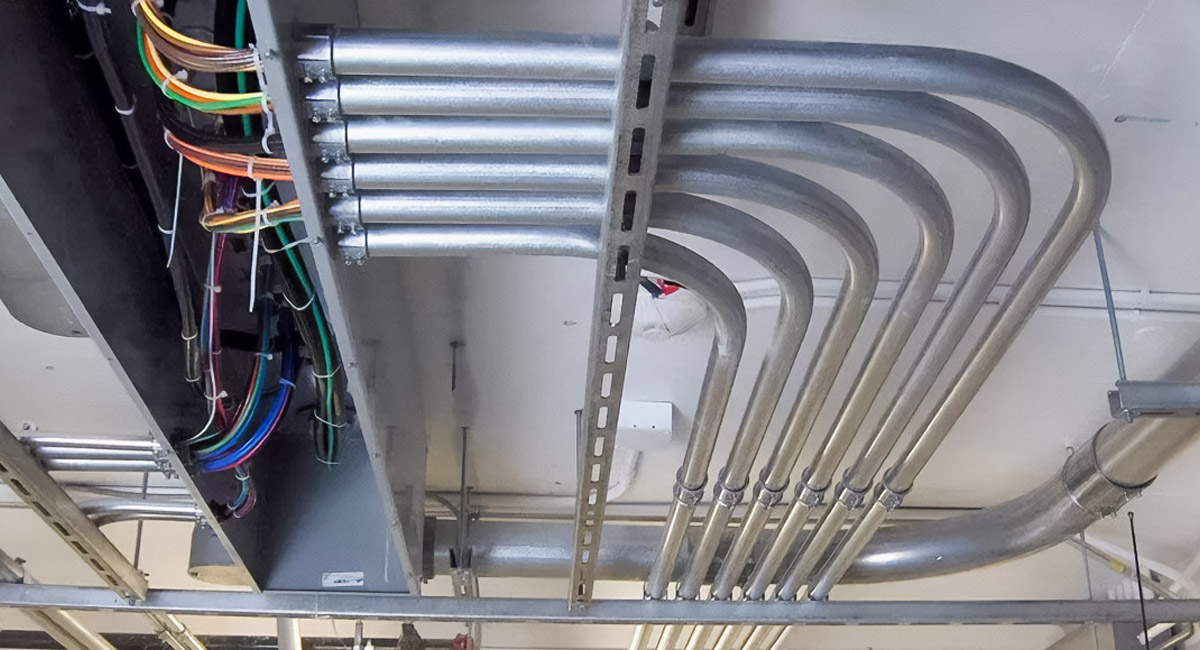

2. Galvanized Rigid Steel (RSC) and Intermediate Metal (IMC)

3. Liquid-Tight Flexible Steel Conduits (LTFC)

Technical Best Practices for the UAE Region

Managing Thermal Expansion One of the most common mistakes in UAE installations is failing to account for material movement. PVC conduits can expand significantly as temperatures rise from a cool 25°C morning to a 45°C afternoon. Professionals must use expansion couplings on long runs. These fittings allow the conduit to slide back and forth within a sleeve, preventing the pipe from buckling or pulling out of junction boxes when the temperature peaks.

Accusamus iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores

Deleniti atque corrupti blanditiis iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores

Ducimus blanditiis iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores